REB-2

The Sierra REB-2 two-ram baler was a machine designed by recyclers, for recyclers and is the ultimate machine for any high volume or high production facility. Available with either a 150 or 250 HP power unit, it has the ability to process a wider variety of materials at a higher rate of production and will ensure your return on your investment. The REB-2 has a unique shear blade that works on waste, fiber, non-ferrous scrap metal, and tires, so there is no need to choose between one material or the other.

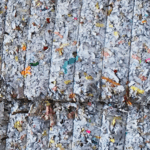

To eliminate material contamination when changing materials, the REB-2 features an innovative bale eject and oversized bale release door combined with full ejection of bales. This feature also produces better bale integrity, especially on materials with lots of memory.

The standard features on the REB-2 two-ram baler gives it unmatched performance and versatility as well, expertly handling a wide range of recyclable materials:

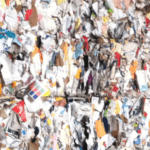

- MSW

- UBC

- PET

- OCC

- ONP

- High grades

- Aluminum

- Non-ferrous metals

- Tires

- And much more…

The REB-2 baler frame is exceptionally constructed to withstand the high pressure generated by the hydraulic system. The floor, sidewalls, and top of the compaction chamber and the extrusion chamber are completely covered with plug welded ½” Hardox 450 replaceable liners. The high pressure hydraulic system translates into machines with the highest production rates and lowest energy consumption in their class.

The REB-2 two-ram baler uses 254 tons of shearing/baling force to form 45”W x 31”H x 62”L bales, with an average production rate and tons per hour of:

REB-2 – 150:

Municipal Solid Waste

- 2400 lbs. average / 37 tons per hour

PET Bottles

- 1400 lbs. average / 8 tons per hour

Mix Plastic

- 1500 lbs. average / 8 tons per hour

OCC

- 1550 lbs. average / 17 tons per hour

ONP

- 1750 lbs. average / 27 tons per hour

Aluminum Cans

- 1200 lbs. average / 10 tons per hour

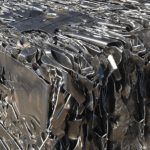

Aluminum Extrusions

- 1400 lbs. average / 9 tons per hour

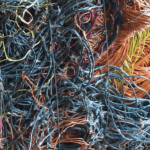

Insulated Copper Wire

- 4000 lbs. average / 20 tons per hour

REB-2 – 250:

Municipal Solid Waste

- 2450 lbs. average / 47 tons per hour

PET Bottles

- 1400 lbs. average / 10 tons per hour

Mix Plastic

- 1500 lbs. average / 10 tons per hour

OCC

- 1550 lbs. average / 23 tons per hour

ONP

- 1750 lbs. average / 38 tons per hour

Aluminum Cans

- 1100 lbs. average / 12 tons per hour

Aluminum Extrusions

- 1400 lbs. average / 12 tons per hour

Insulated Copper Wire

- 4000 lbs. average / 25 tons per hour

Bag it or Wrap it.

The Sierra REBs can be outfitted with specifically designed bagging and wrapping systems.

Considering a two-ram baler for your MSW?

There are immediate cost savings that can be realized through bailing MSW, the most important benefit is improved density of the material set in the landfill. The in-place density can be as much as 50% greater than those reached by compactors. This benefit will show up in the extended landfill life and a smaller working face therefore less daily converge. If the bales are not bagged or wrapped, daily cover is usually reduced from 6” to 2” saving valuable air space as well as material and handling. When they are bagged or wrapped daily cover could be eliminated entirely.

WANT TO KNOW MORE?

Material Processed

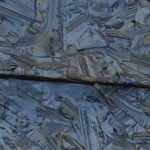

- Aluminum Extrusions

- Aluminum Sheet

- Copper Tubing

- Copper Wire

- Radiators

- Stainless

- Solid Waste

- PET Bottles

- OCC

- News

Download the full product details

Download the full product details