REB-X

Overview:

Utilizing Sierra’s expertise and experience with portable machines and two-ram balers, the REB-X two-ram baler is easily transportable while maintaining a heavy-duty construction, remarkable performance, and the ability to process a variety material.

The innovative REB-X portable two-ram baler offers the versatility and flexibility recycling facilities need in today’s market:

Multiple Facilities

The REB-X portable two-ram baler is ideal for companies that have multiple facilities but don’t do the volume in any of those facilities to justify a single piece of equipment per facility. The REB-X can be placed on a rotational basis and be moved around to the different facilities to bale material.

Maintenance Shutdown

The REB-X can also be beneficial during maintenance shutdown. When stationary equipment needs to go down for maintenance the REB-X can be used in its place instead of being down and backlogging material, eliminating downtime.

Demolition Projects

The REB-X can be brought onsite to demolition projects. Instead of hauling non-ferrous material from the demo location to be processed elsewhere the REB-X can bale the material onsite and have it ready to ship directly to the consumer.

Disaster Cleanup

The portable REB-X two-ram baler can be an aid in disaster cleanup. TheREB-X can be transported to areas affected by hurricanes, tornados, floods, etc., instead of hauling the material to facilities that could be miles away.

Landfill Projects

The REB-X can be used to densify material during landfill mining projects when material needs to be bailed to gain weight.

Application for Rural Areas

The REB-X does not require an infrastructure setup, so it is an ideal machine for rural areas where access to electrical power is difficult or impossible to get.

General Information

The standard features on the REB-X gives it unmatched performance andthe ability to process a wide variety of materials:

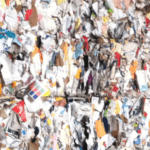

- MSW

- UBC

- PET

- OCC

- ONP

- High grades

- Aluminum

- Nonferrous metals

- And much more…

The REB-X uses 143 tons of shearing/baling force to form 46” W x 31” H x 62” L bales, with an average production rate and tons per hour of:

Solid Waste

- 2300 – 2500 lbs. average

PET Bottles

- 1250 – 1400 lbs. average

Aluminum Cans

- 1050 – 1150 lbs. average

OCC

- 1400 – 1600 lbs. average

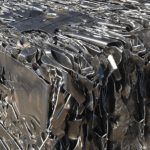

Stainless Steel

- 3500 – 4500 lbs. average

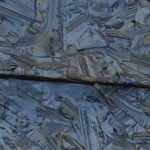

Aluminum Sheet

- 1500 – 2000 lbs. average

Aluminum Extrusions

- 1200 – 1400 lbs. average

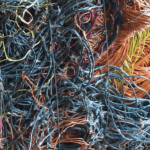

Copper Wire

- 3300 – 5500 lbs. average

The REB-X baler frame is exceptionally constructed to withstand the high pressure generated by the hydraulic system.The floor, sidewalls, top of the compaction chamber, and the extrusion chamber are completely covered with plug welded Hardox 450 replaceable liners. The energy efficient hydraulic system translates into a machine with high production rates and low energy consumption.

WANT TO KNOW MORE?

Material Processed

- Aluminum Extrusions

- Aluminum Sheet

- Copper Tubing

- Copper Wire

- Radiators

- Stainless

- Solid Waste

- PET Bottles

- OCC

- News

Download the full product details

Download the full product details